If you want to know how to make fun and functional stamps with laser compatible rubber, then you’ve come to the right place! In this quick guide, we’ll show you how we made ours.

Making custom rubber stamps are easy to make, and they can be used for fun or for professional applications. You can download the file below to either use as-is, or as a template for your own designs.

We Used:

- Laser Compatible Rubber.

- A Laser Cutter.

- Glue.

- A shaped wooden block.

- Some Ink.

- Download our DXF file here.

Step 1 – Create your designs:

When creating designs, we’ve found that simple designs often work the best. Also, make sure to draw the border for the stamp.

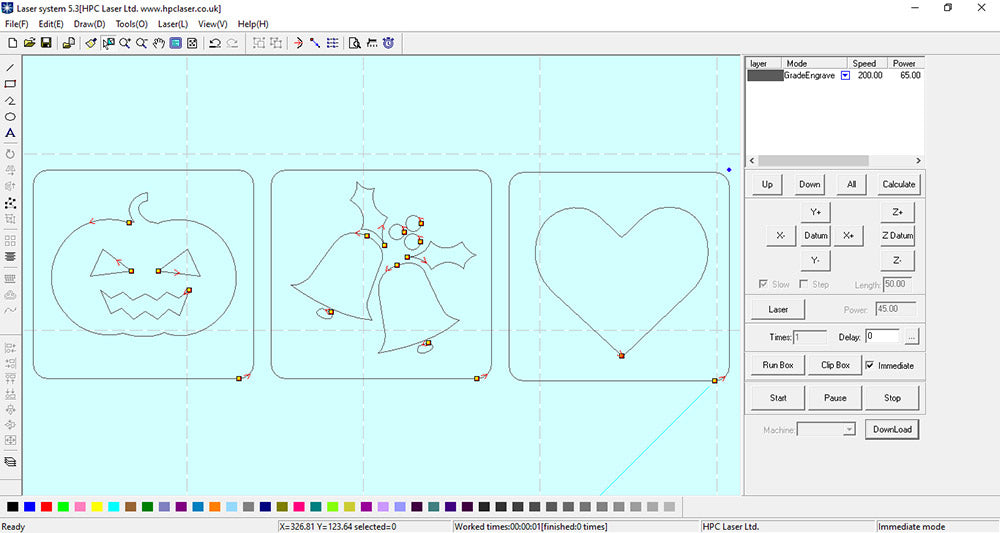

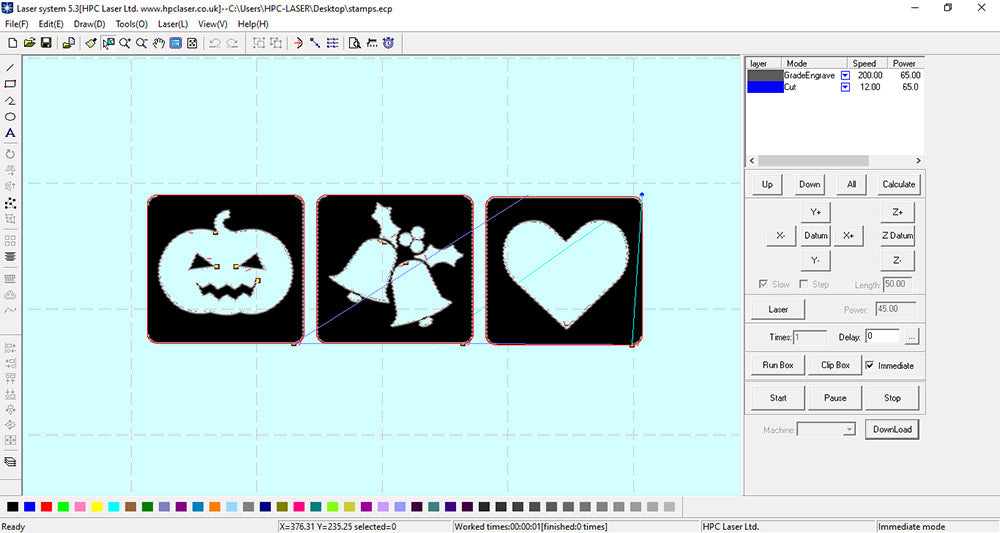

Step 2 – Import into your laser cutter software:

Once imported into your laser cutter software, make sure to select engraving. Then, duplicate the perimeter and ensure that you have it set to cut.

You can also preview the design before you send it to your laser cutter.

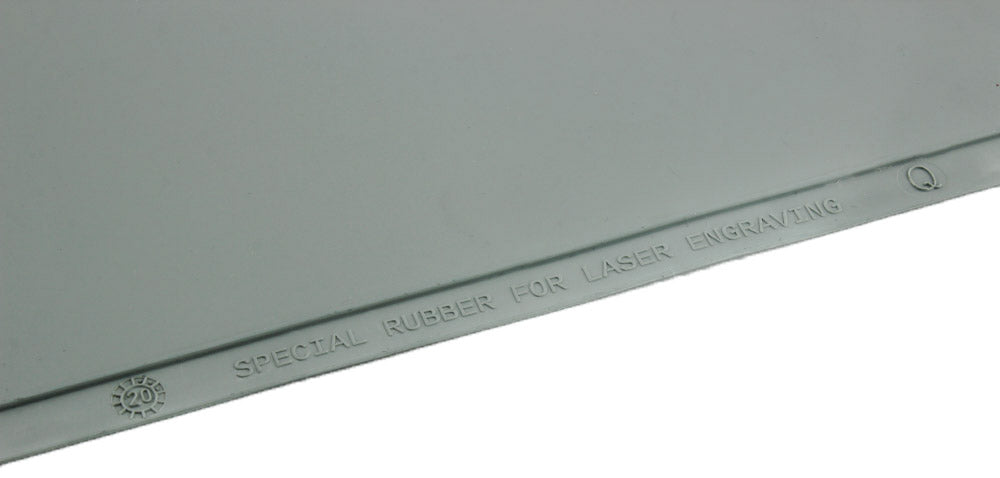

Step 3 – To the laser cutter with the laser compatible rubber:

Load your laser cutter with the laser compatible rubber and set it going. Once cut there may be some residue left, most of this should easily wipe off.

Once removed from the laser rubber sheet, you should be left with the three individual stamps.

Step 4 – Mounting the stamp:

Mount your stamp onto something solid, we glued ours to a block of wood. This gave us a sturdy stamp that is easy to hold and use.

Step 5 – Stamping:

Stamp away! You can make some very fun designs, so why not try using these for scrap-booking! You could also print company logos, or use them to stamp official company documents. They would also be great for customising Christmas cards or present tags! Alternatively, just let the kids loose with some ink and a large piece of paper– extra bonus points for children not covered in ink at the end!

About The Material:

The 2.3mm Grey Laser Compatible Rubber A4 (210mm x 297mm) sheets that we used are highly versatile and are the perfect choice for a rubber that will be cut with a laser. Although it has a number of potential uses, it’s high resistance to alcohol and water based inks makes it the ideal choice for making custom rubber stamps. Here are a few its main features;

- Low smell when cut on a laser.

- High resistance to alcohol and water based inks.

- Very durable.

- High friction.

- Easy to cut.

- Waterproof.

Sign up to our Newsletter!

If you’ve enjoyed our content, why not also sign up for our newsletter? That way, you’ll never miss our new product updates, offers, news and more. Sign up today, click here.