In today’s world of daily rising raw materials prices, increased consumer prices are a reality that we are all now dealing with. If you manage a materials budget for a school, what do you do? Do you continue to do what you typically do but pay extra, or do you look around at some new alternatives?

We stock a range of value acrylic sheets that we believe meet the needs of most of our customers. Maybe you’ve seen it but haven’t yet tried it out. Let us give you some useful information to help you better consider your options. First, let’s have a look at what acrylic is, so we have a yardstick.

Yardstick – What is Acrylic?

Acrylic is a term that is used for a specific type of plastic, polymethyl methacrylate. You may have also seen the term plexiglass used, but Acrylic seems to be the most widely used term. Acrylic is classed as a thermoplastic, meaning that it softens when heated. This makes Acrylic extremely easy to work and shape and is one of the reasons that it is so popular in schools and among makers.

Acrylic is often used as a direct replacement for glass. It’s 50% lighter than glass, 30 x more impact-resistant than glass, and transmits more light than glass of the same thickness. Additionally, when Acrylic breaks, it cracks rather than covering the entire area in shards of sharp material.

There are two distinct types of acrylic and they are classified by the way that they have been manufactured. Extruded and Cast. Cast acrylics are the premium option as it is more expensive to make and results in an end product with more desirable qualities. Cast acrylics are easier to work, more durable, and have more chemical resistance than extruded. Extruded are often sold as a cheaper option. Many manufactures will produce both types for a broader market appeal.

What Is Value Acrylic, how does it measure up?

At the time of writing, we stock almost 20 lines of cheap acrylic sheets and they all have two things in common. Firstly, they are all made from cast acrylic and second, they are much cheaper than other cast acrylics.

To all intents and purposes, value cast acrylic can be used in all of the same ways that the branded counterparts can. It can be worked in the same way to produce the same results, and it can be used in all of the same applications. In all bar one respect, you will have the same experiences and outcomes. The main difference between these cheap acrylic sheets and branded ones is colour consistency. If you have two sheets of value cast acrylic from different batches, it’s highly likely that there won’t be a perfect colour match. For most D&T applications, this won’t be a problem. But if you manufacture items for sale, then consistency of outcome is a primary concern.

What exactly can Cast Value Acrylics be used for?

Let’s ditch the generalisations and look at some specifics. There are lots of things that are made with cast Acrylic and our value cast Acrylic can be used for all of them

Typical uses include; point of sale, model making, signs, artistic and architectural installation, casings, custom enclosures, fragrance, lotions, or other solvents, instrumentation readouts, dial covers, and much more.

Working with Acrylic sheets:

Acrylic is a versatile material that can be cut, drilled, laser cut and thermoformed. Acrylic is a thermoplastic which means that when it is heated above 140-180°C it becomes flexible. This allows the material to be formed into the required shape or bent. Once the material cools below 85°C it becomes rigid again.

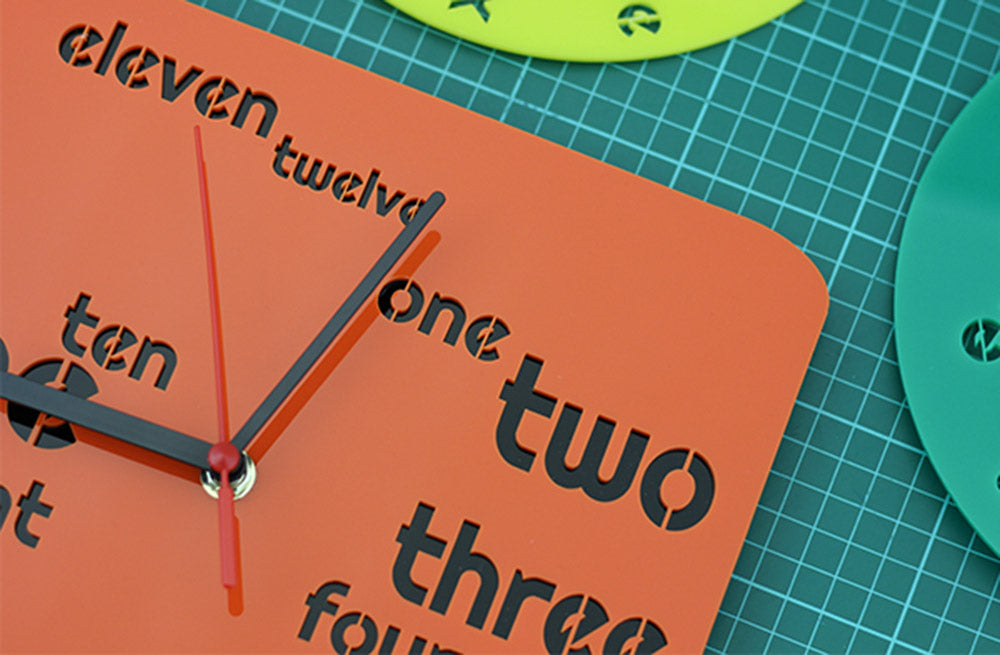

Acrylic sheets are often shaped using a CNC router or laser cutter. The edge of laser cut Acrylic has a pleasing polished look. If you look carefully at the edge of a piece of laser-cut Acrylic you can often see slight vertical lines that are caused by the pulses a laser uses when cutting.

If you want to get a perfectly smooth finish on the edge of a piece of machined Acrylic a polishing technique can be used. Typical polishing techniques include diamond polishing and flame polishing.

It also possible to etch the surface of an Acrylic sheet using a laser cutter. This can produce some very pleasing visual effects. We’ve found that cutting value acrylic is no different to cutting branded acrylic on the laser cutter. If your lenses are clean and your height properly calibrated, cutting and engraving is a breeze.

All of the above information and techniques are as valid for branded acrylic and for the cheap acrylic sheets that make up our Value range.

More detailed information and resources on working with Acrylic can be found in our resource section.

Conclusion:

As we’ve covered, Value acrylic can be used in place of branded acrylics for all applications. The main pro is that they are significantly cheaper. The main con is that colours may vary from batch to batch. If your primary concern is budget then maybe the cheap acrylic sheets of the Value range makes sense for you. Why not have a look at our range of value acrylic and see if we have what you need. If not, get in touch and we’ll see what we can do!

If you enjoyed this guide, make sure you don’t miss out on any other new free learning resources by signing up for our newsletter here.