Emma brings you a make that could come in handy: two designs of hand-fan that will keep you cool and look stunning! Customising these to match outfits and aesthetics is a breeze (pun intended) by switching out colours and designs to suit your needs. You can even laser cut appliqués for your fabric fan for added glam. Read on to find inspiration!

Before we start, this zip file contains all of the files needed for both of the makes below, you can grab it here.

Filigree Fan:

Fine detail cut into high-grade plywood creates an elegant and delicate fan design that wouldn’t look out of place on a beach or used with a fancy outfit on a balmy evening

We have used:

- Laser Cutter

- 1 x Sheet of 2mm Ceiba Plywood.

- 1 x Reel of Fishing Line.

- 1 x M3 30mm Pan Head Screw.

- 1 x M3 Hex Nut.

- 2 x M3 Plain Washer.

How It’s Made:

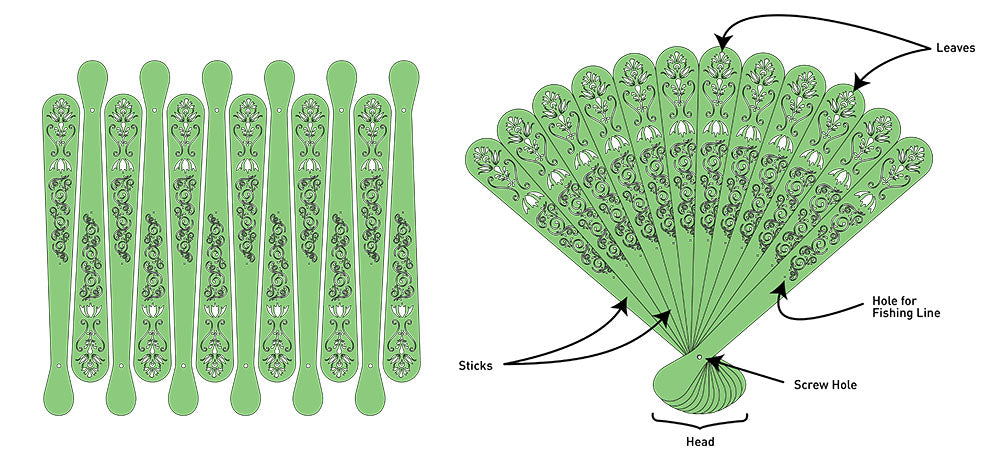

Step 1 – Grab the files and check them out:

Check out the working file! You can download the filigree fan files at the top of this blog in DXF, SVG and AI. Below is a demonstration of what the DXF will look like when opened, alongside a demonstration of the way the fan will be constructed. The second diagram labels various parts of the fan, in order that you can follow along with the instructions more easily.

Step 2 – To the laser cutter:

Laser Cut the DXF.

Step 3 – Clean up/finish the wooden parts:

If using wood, prepare it as desired. We sanded the pieces to remove any burning on the faces and edges. There are lots of additional finish options you could consider; Natural sanded, varnish, stain, or embrace the burn and go full Shou-Sugi-Ban.

Step 4 – Putting the structure together:

Put the 30mm M3 Screw through the screw hole, using washers on both the front and back, then screw the M3 Hex Nut on.

Step 5 – Setting the range of movement:

Limit the range of motion for the leaves using fishing line. You can also use thread, but it may not be as strong. We have tied the fishing line behind each of the leaves so that they are held where we want them to be when the fan is unfurled. This is all except for the front-most leaf, which is tied in the front.

You’re done!

Fabric Fan:

The use of a fabric panel means you can customise this to your heart’s content. Whether you laser-cut your own word appliqué, use a patterned fabric or leave it plain, the customisation is endless! Check out the inspiration below these instructions for more customisation ideas.

We have used:

- Laser Cutter.

- 1 x Sheet of 1.5mm Black HIPS.

- 1 x M3 16mm Pan Head Screw.

- 1 x M3 Hex Nut.

- 2 x M3 Plain Washer.

How It’s Made:

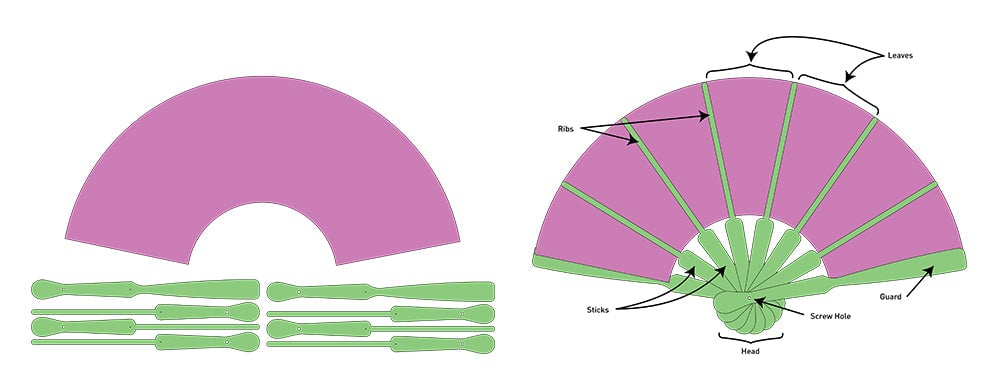

Step 1 – Grab the files and check them out:

Check out the working file! You can download the fabric fan files at the top of this blog in DXF, SVG and AI. Below is a demonstration of what the DXF will look like when opened, alongside a demonstration of the way the fan will be constructed. The second diagram labels various parts of the fan, in order that you can follow along with the instructions more easily.

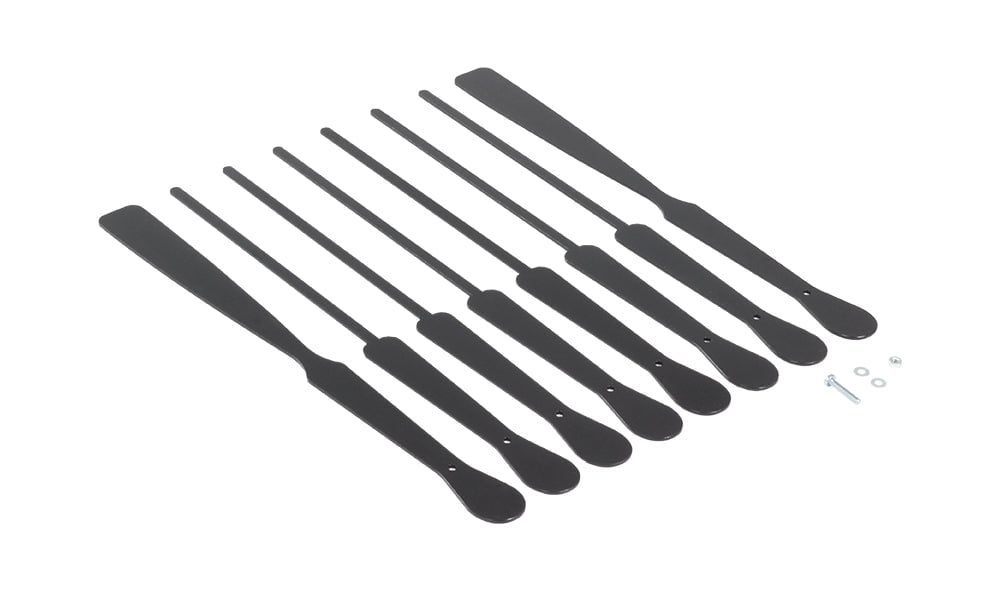

Step 2 – Cutting out the parts:

Cut the Skeleton of the Fan out on the laser cutter – you should have six central sticks and two outer guards.

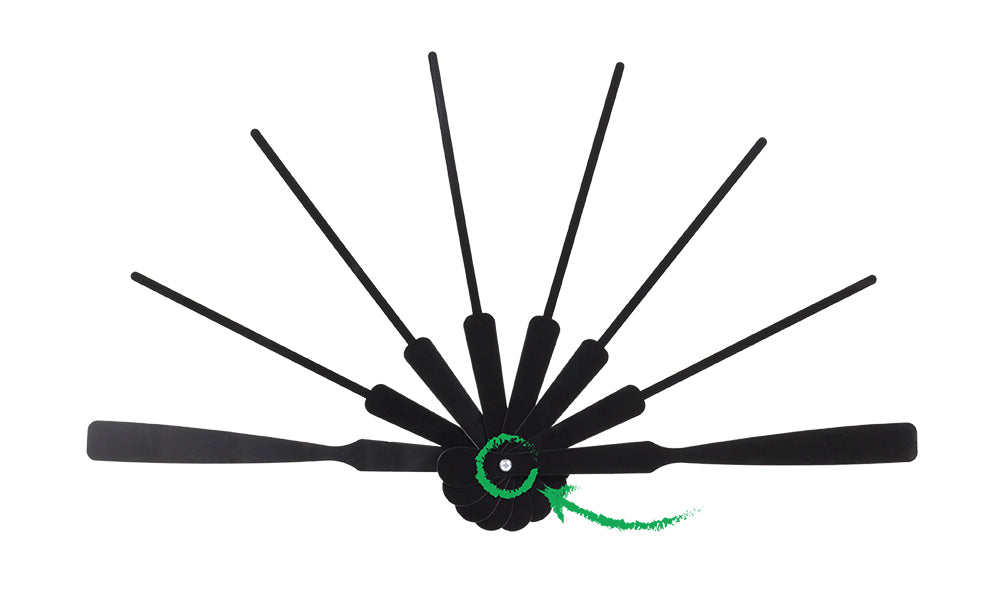

Step 3 – Making the frame:

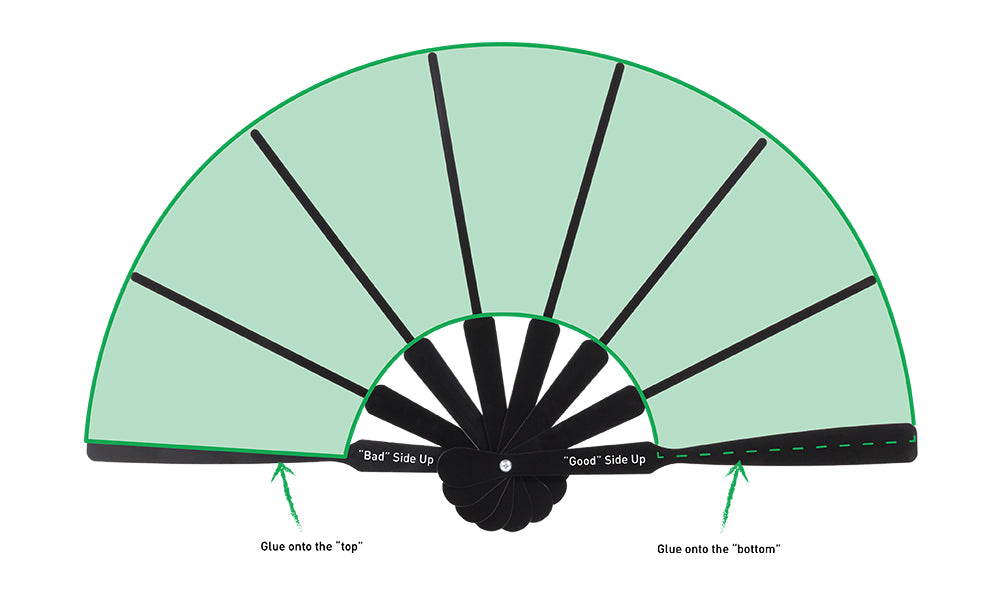

Using a 16mm M3 Pan Head Screw, connect them all together with the guards on the outside with their “good” sides facing outwards if your material has a “good side”. Make sure to use a washer on both sides, and attach with an M3 Hex Nut.

Step 4 – Cut your fabric:

You can either print the shape out using the DXF, or you can laser cut the fabric. This is possible, though it is advisable to check with your laser cutter’s manufacturer for more detailed information.

Step 5 – Attaching fabric to the frame:

Hem or seal the edge of the fabric (e.g. melting or gluing), then attach your fabric to the ribs – we used a fabric glue. Fabric glue can be used to attach fabrics to a number of different materials, not just other fabric, though some fabric glues are specifically just for fabric-to-fabric bonding.

Step 6 – Glue in place:

Glue the ends of the fabric to the back of the guards, as shown in the image.

Once the glue is dry, you’ll be done!

Why not try out some of these customisation ideas for your fabric fan?