This tutorial explains how the Electro-Fashion Cat design is screen printed on to a piece of felt. The screen printing of that cat is performed using an industrial screen printing process. This is simply a more automated version of the traditional manual screen printing process. The Electro-Fashion Cat is an ideal introduction to e-textiles. When complete, the cat’s eyes will light up when the right ear is squeezed.

Step 1

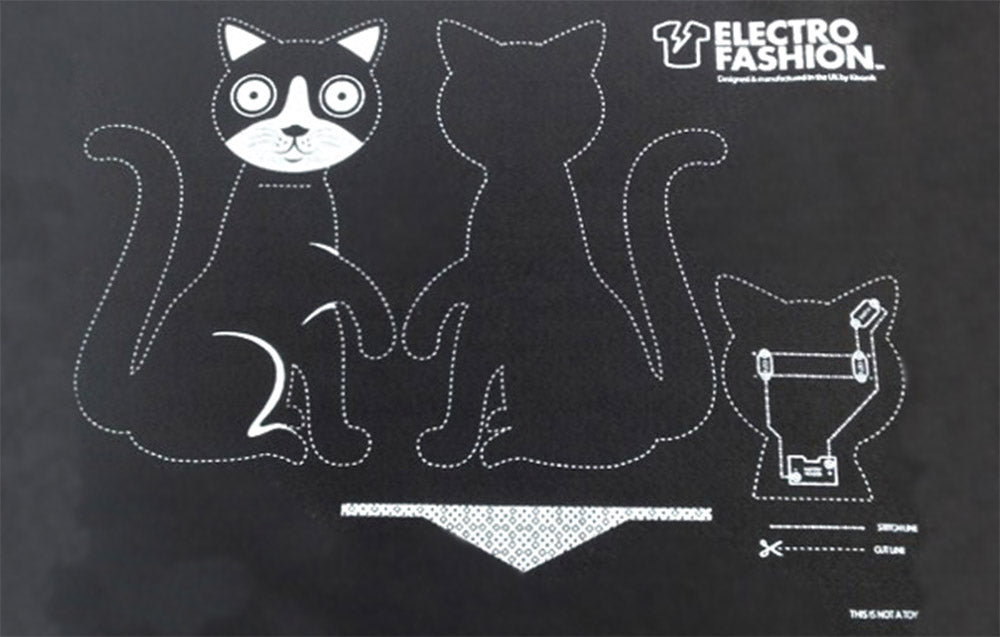

The first stage is to make the stencil. This stencil has holes that allow paint to pass through the areas that we want to print. The completed stencil for the cat is shown above.

Step 2

The second step is to fit the stencil to the screen printing machine. Once fitted the squeegee blade is then fitted as shown above.

Step 3

A piece of feIt can then be presented to the back of the machine. It is first placed on a board that automatically moves across and under the stencil. It then rises to make a firm connection against the back of the stencil.

Once the felt is presented to the back of the stencil the machine looks like the photo above.

Step 4

The squeegee blade then passes over the stencil and forces the paint through the areas of the stencil that we want to print.

Step 5

Once printed the material is automatically removed from the back of the stencil so that the pieces of felt can be removed from the machine. The cat design uses only one colour (white). If more than one colour was used in the design additional stencils would be used for each colour. The piece of felt would rotate around and be presented to each stencil in turn until all the colours have been printed.

Step 6

The next step is to dry (cure) the ink. This is done by using a special oven. The material is placed on a conveyor which passes the material through the oven. The oven heats the paint to a temperature that causes it to dry.

Step 6

Once the material has passed through the oven the ink will be dry and the screen printing process is complete. Download a pdf version of this page here ![]() Learn more about the author read more »

Learn more about the author read more »