An important part of 3D printing is proper calibration of the printer. Fortunately, the AutoMaker for Robox simplifies this by guiding the user through three software-led calibration processes. Before starting your first print, it is a good idea to run through these processes. The Robox has two nozzles on the print head, a fine 0.3mm nozzle and a draft 0.8mm nozzle. It is important that the printer knows the exact distance between the two nozzles, especially when a print uses both nozzles such as when printing in draft quality but using support material (which is done with the fine nozzle). As with the other calibration processes, the ‘Nozzle Alignment’ procedure can be accessed by clicking on the ‘Calibrate’ button at the bottom of the status screen. Note that you should perform the ‘Nozzle Height‘ and ‘Nozzle Opening‘ calibrations first as this calibration process involves printing a test model.

An important part of 3D printing is proper calibration of the printer. Fortunately, the AutoMaker for Robox simplifies this by guiding the user through three software-led calibration processes. Before starting your first print, it is a good idea to run through these processes. The Robox has two nozzles on the print head, a fine 0.3mm nozzle and a draft 0.8mm nozzle. It is important that the printer knows the exact distance between the two nozzles, especially when a print uses both nozzles such as when printing in draft quality but using support material (which is done with the fine nozzle). As with the other calibration processes, the ‘Nozzle Alignment’ procedure can be accessed by clicking on the ‘Calibrate’ button at the bottom of the status screen. Note that you should perform the ‘Nozzle Height‘ and ‘Nozzle Opening‘ calibrations first as this calibration process involves printing a test model.

Step 1

After selecting the ‘Nozzle Alignment’ calibration option and clicking the ‘Start’ arrow at the bottom right of the screen the printer will begin to heat up and begin printing the calibration pattern.

Step 2

You should end up with a printed pattern like the one below.

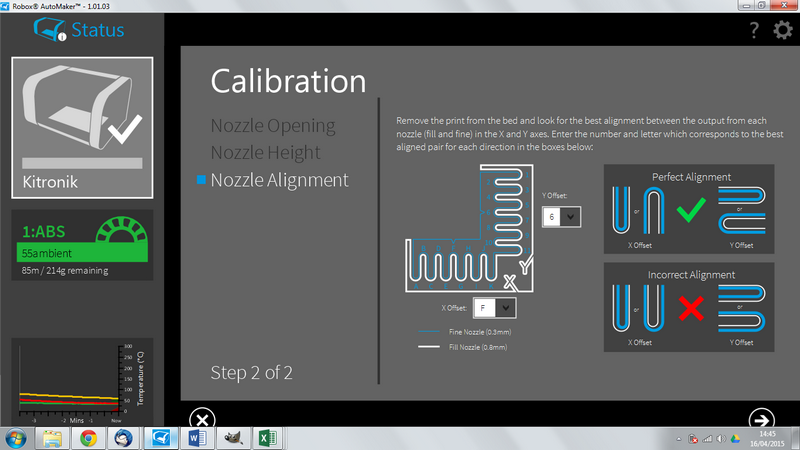

The screen will change to the one in the image below. Take a look at your printed pattern and select the wave shapes on the X and Y axis that look closest to the ones in the grey box labelled ‘Perfect Alignment’.

Your Robox printer should now be fully calibrated, assuming you performed the Nozzle Opening, Nozzle Height and Nozzle Alignment calibration processes in that order! Remember that you can go back re-do any of these if you aren’t happy with the results or think you have a mistake.