Create a layered colour changing shadow box using polypropylene, an RGB LED Strip with Pattern Selector and USB Power Lead. Download the dxf zip file and follow, our in-house animator/designer, Kev’s instructions.

This simple but effective make can creatively inspire students and also hit many different elements of the school curriculum.

What you’ll need:

- White Polypropylene Sheet.

- Black Polypropylene Sheet.

- RGB LED Strips (30 pack).

- 1 x A5 white paper or card.

- Glue

- Something to use as the spacers described in step 2.

- Laser Cutter or knife and scissors.

- This DXF design.

Step 1 – Your Design:

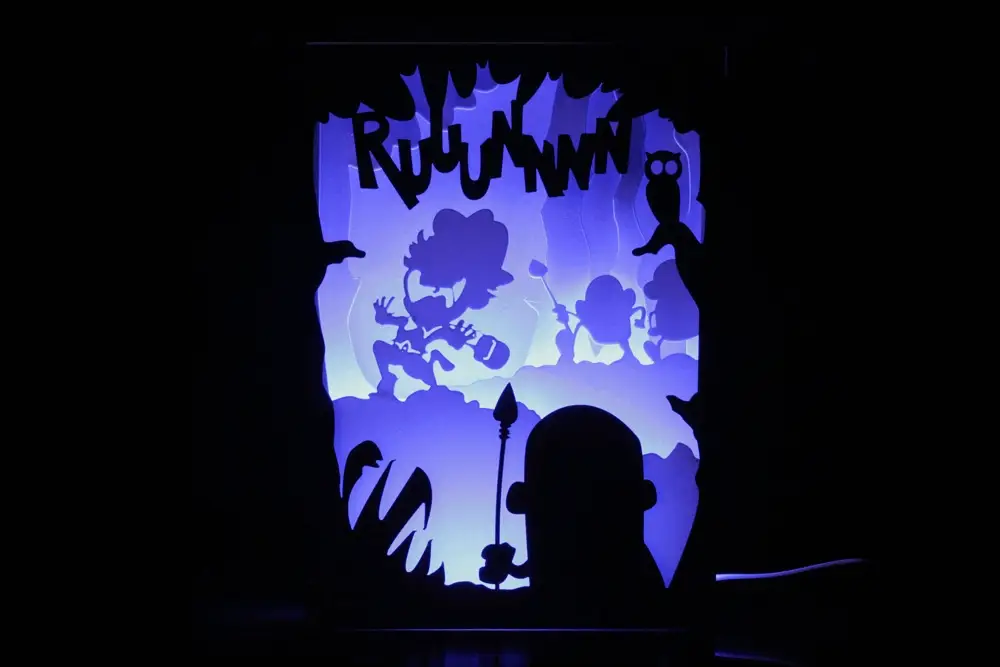

If you wish to use our treasure hunter being chased by the natives, feel free to download our DXF file, made up of each individual layer, or get the students to draw or design their own.

Cut each layer using a laser cutter, craft knife or scissors, making sure to cut the top layer out of the black and all other subsequent layers in white.

Step 2 – Layers, Assemble:

Using folded pieces of card, acrylic cut-off’s, straws or anything else you can get your hands on, stick these in the corners of each layer (bar the black layer) to create space between each layer. We’ve used some clear acrylic cut-off’s and super glued them in the far corners. You might want to experiment with the distance between each layer, but we found that about 1cm between each worked well.

Use the sheet of paper or card as the last sheet of the shadow box, with spacers between said piece and the polypropylene sheet in front.

Step 3 – Let there be light:

Once the glue has set place the LED strip between the 2 layers. Feel free to experiment where the light goes, as we found the most effective was not between the back 2 layers, but the next one in front.

Turn on the strip to the desired pattern and then flick off the classroom lights…

Send us your photos of students’ finished work and we’ll share them on our socials.

*If you want to try an even more cost effective shadow box, you can reduce the size to A6 or replace the polypropylene with card (you may want to check on thicknesses), but be aware that the spacers need to be fairly light otherwise it could come crashing down…