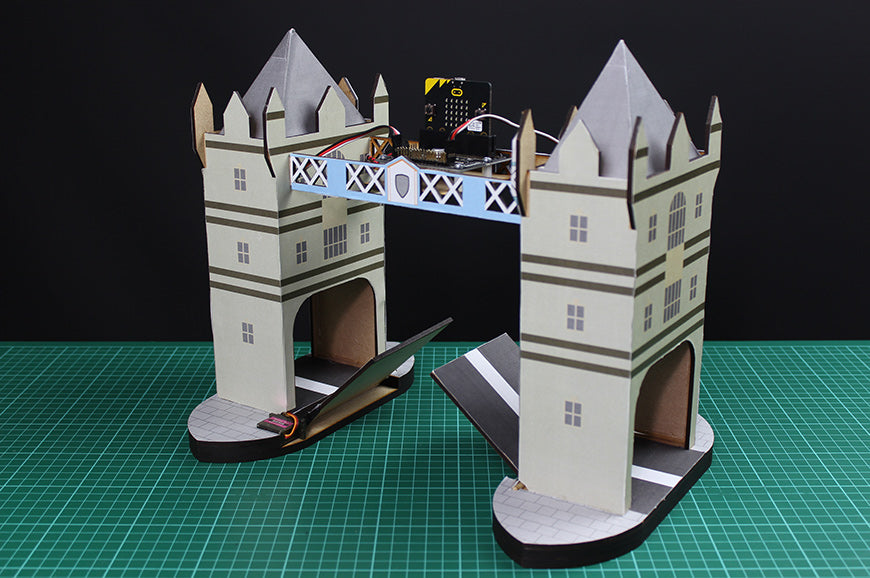

At the centre of our Kitronik :CITY layout we had at BETT 2019 was our microbit controlled model of Tower Bridge. The model featured our 16 servo driver board. We demonstrate how we made it and also how you can make one for yourself.

In this model we used:

- BBC microbit.

- 16 Servo driver board.

- 2x Metal gear mini servos.

- 30cm Servo extension cable.

- 3mm MDF.

- 6mm MDF.

- 4mm Dowel.

- M3 Screws and Nuts.

- Download the DXF files.

microbit Servo Driver Tower Bridge – BETT 2019 Part 4:

Designing:

Designing the bridge was a bit of a mechanical challenge when making the Kitronik :CITY layout. The mechanism needed to be robust enough to last a whole week at the BETT 2019 show. It also needed to be simple enough to be taken apart and not spoil the look of the model. I decided the best way to mount the servo and hinge was friction fit in three layers of MDF. The 6mm bottom layer is a base that starts the shape, the 6mm middle layer holds servo. While the top 3mm layer acts as a simple bearing for the bridge and also holds the servo.

Making:

Laser cut the 3mm pieces together. Remember to change your laser settings to a slower speed before cutting the thicker 6mm material.

*Tip: After finishing a laser cut, look for small pieces that may have fallen out to see if the cut has gone all the way through. If you can’t see any, gently press on a piece without moving the surrounding material to see if it is free. If it hasn’t cut all the way through, you should now be able to close the laser and go over the same cuts again and save wasting the material. *

Test fit the towers together. There should be a small curve in the corner of the side pieces where the servo will fit, make sure these are on the same side. The three baseplate layers are labelled so keep note of which order they go in. PVA glue the layers together and secure them in a vice or clamp while you glue the tower itself (we used hot glue for this as the other buildings).

For some added reliability we used metal gear servos. Once the glue is dry, test fit the whole bridge. Including pushing the servo into place to test that it will be secure. You may have to take some material off with a small file if it doesn’t push all of the way into place.

Applying the Artwork:

There are lots of tricky corners to cut on this model (particularly in the gantry above the bridge). This makes applying the artwork quite delicate. First, we cut all of the panels with a craft knife. Then used a combination of double-sided tape for the larger simpler panels, and glue stick for the more intricate corners. For the pointed roof, cut sections of the grey page and apply them until there is no MDF showing.

The Electronics:

This model runs from our 16 servo board. Here it is only using 2 servo outputs. So, there’s plenty more for any other of your own models you would like to run in your layout. You will need two servo extension cables to reach from its perch on top of the gantry down to the servos. Tuck the excess into the tops of the towers.

Coding The microbit:

Sweeping a servo so that the bridge slowly lifts rather than jolts upright in one go takes some thinking (although that would make driving in London much more exciting come to think of it). To do this, we make a variable for the servo position “Pos” rather than writing commands directly. When activated, we run a loop that changes the “Pos” value by 1°. This then repeats this 45 times with 100ms pauses.

*Note: In our code we’ve used a loop that repeats 90 changes of 0.5**° for a smoother sweep. *

When a command is sent from Big Ben every two minutes, or when button A is pressed, the code is set to lift the bridge. Big Ben is continuously sending out time information. All the microbit needs to do is identify the even minutes to get an interval of 2 minutes between each lift.

Kitronik :CITY Resources:

Our Kitronik :CITY stand attracted a lot of attention at BETT 2019. Many of our visitors also expressed a desire to make something similar once they returned to their schools. We decided to help out by producing the guides below. Each part of the :CITY has its own guide and each guide has all of the files, code and also instructions included. Additionally, if you or your students tackle any of the builds below then we would love to see the pictures. With your permission, we would also like to feature them in the Gallery (Gallery@kitronik.co.uk).

| Make A microbit Controlled Kitronik :CITY: | |

|---|---|

| Kitronik :CITY Part 1 – Laser Cut :MOVE Mini Garage. | Learn How! |

| Kitronik :CITY Part 2 – :MOVE Mini Football Stadium. | Learn How! |

| Kitronik :CITY Part 3 – Klimate, microbit & ZIP Halo Big Ben. | Learn How! |

| Kitronik :CITY Part 4 – Servo Driver Board Tower Bridge. | Learn How! |

| Kitronik :CITY Part 5 – Robotics Board London Eye & Turbine. | Learn How! |